A biotech company wanted to focus its risk management efforts on its most vulnerable suppliers. However, with over 1,000 individual suppliers and multiple materials sourced from each, developing a robust critical list was a complex task.

Before an analysis could begin, it was important to narrow the definition of ‘critical’ to those that were unique or difficult to replace. This required a criticality ranking methodology that could be applied quickly across materials and their suppliers.

Two initial filtering methods helped to create a more manageable list of critical materials that could be extracted from the materials management system (MMS).

1) The company’s procurement team was organised in a category-management-based structure. This had advantages from the filtering perspective e.g. non-critical categories could be excluded from the outset.

2) One of the fundamental principles of SCAIR® is to follow the brands/products with the highest revenues. Therefore, the study was limited to critical supplier materials for all brands over the organisation’s materiality threshold.

The filtered export from the MMS was presented in an Excel format which included:

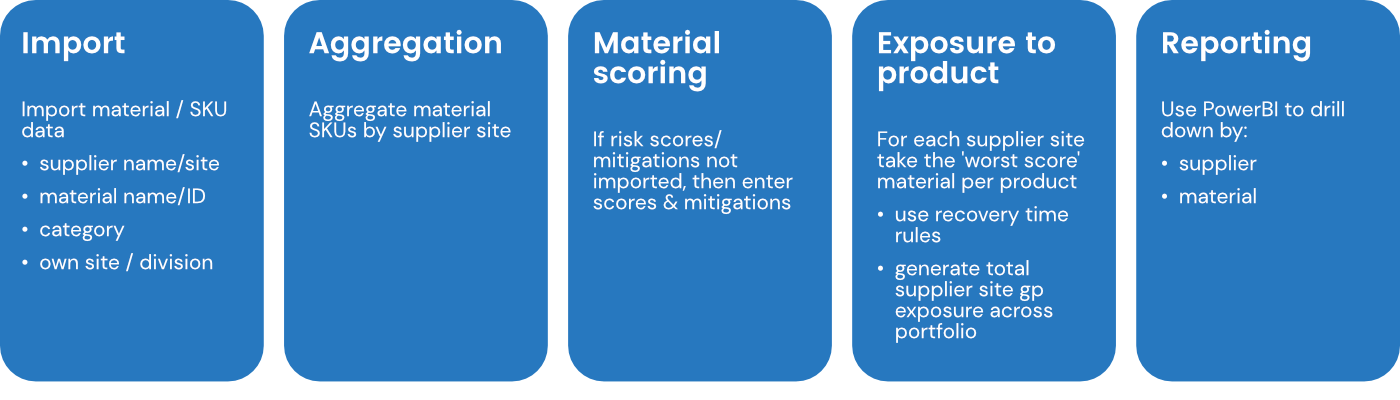

This Excel spreadsheet was imported into SCAIR®, which then started the heavy lifting as follows:

Only suppliers that scored above an agreed level were passed through for individual supplier Gross Profit (GP) exposure estimation. To further speed up the exposure estimation step, typical recovery times were agreed based on Material Types in order to generate some ‘first pass’ loss estimates for further investigation.

The company developed a targeted hit list for investment/mitigation based on vulnerability and GP exposure – rather than the traditional procurement approach of measuring risk by how much is spent with a supplier.

It could also put a financial loss against each supplier site, which facilitated the cost-benefit discussions for mitigation.